SST Shop Talk

CNC 101

The Basic Parts of a CNC Machine

If you carve your name on a wood using a very sophisticated font, you’re lucky if you’ll finish your first name in 24 hours perfectly. Traditionally, wood and metal crafting was very expensive and labor intensive because every aspect of the manufacturing is done by hand. There were minimal machine intervention to assist with the intricate designs.

Today, with the help of technology, wood carving, metal molding, cutting and even finishing can be done simultaneously with very few man hours. In fact, a company is deemed unproductive if it mass produces products every day BY HAND.

CNC (Computer Numerical Control) machines are in demand in industries where hands are better off pushing buttons than doing actual labor. Industrial giants and hobbyist both benefit from a CNCs accurate, speedy and flexible machining capabilities.

The CNC machine is actually a factory of its own. There are different parts that have specific functions. Let’s get to know the “factory workers”.

THE VICE

The Vice is what holds the material which is to be cut or molded. It is important that the vice must be tight; so the material will be held securely. When the CNC machine starts to operate, the material will dash out of the vice if it is not secured. The vice usually works like a clamp that needs to hold the material not just securely but also in the right position.

THE GUARD

The Guard—just like any other guard—works like a “protection” to the person operating the CNC machine. Once the CNC starts working, scraps of the material can “shoot off” at high speed. This is very risky for the operator if a piece hits him/her. The guard completely covers all the hazardous sides of the CNC machine.

THE CHUCK

The chuck holds the cutting tool. Sophisticated designs require maximum chuck precision so the actual design can be realized.

THE MOTOR

The motor rotates the chuck at very high speed. It is hidden and protected inside the machine. You have to take care of this part very carefully. Nowadays, cooling and lubrication is automated in most CNC machines. Usually, if this part doesn’t function well, it is the most difficult to treat. It is advised to have a CNC technician handy all the time.

THE LATHE BED

Like the foundation of your home, this is the sturdy base of the CNC machine. It is connected to the headstock and aids the carriage and tailstock to be parallel with the spindle’s axis. It is securely bolted so it remains unshaken by the vibration of the machine when it starts operating.

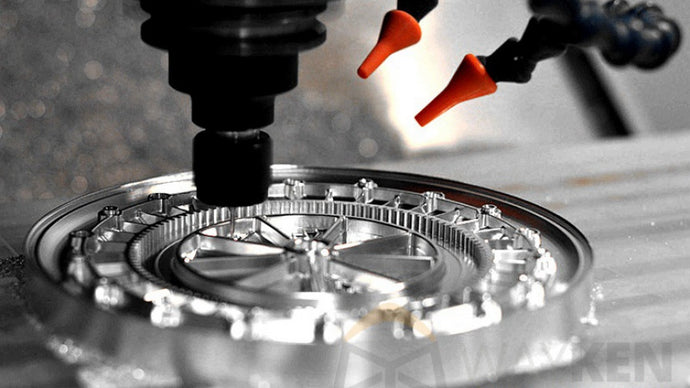

THE CUTTING TOOL / CUTTER

This is the where the first-level shaping occurs. The cutter is usually made from high quality steel so as to cut the specific material fed to the CNC machine. Different cutting tools are used for different materials and/or operations.

As a businessman, it is important that you get to know your employees, bond with them and understand their nuances. When you have CNC machines working for you, it is equally important that you understand the CNC parts as well. Do not be fooled by the CNC machine salesmen who court your interest because they are usually just after your purchase.

You have to master what comprises these machines, what makes them dysfunctional and most of all, what makes them wok in harmony. Check on your parts, calibrate your equipment, and learn everything about your machine! company.

The Programmer

The first person is the CNC programmer. He is like the "playmaker". He will create the programs that the CNC machines are intended to execute. Since the programs are in the form of CNC codes fabricated like sentences, he should have mastered these codes because they work like a different language. The regular CNC machine can use up to 50 codes, so that's like learning 50 new words for the newbie.

Also, the programmer should have at least and engineering or machining degree. Remember that the CNC machine will only execute WHAT IT IS PROGRAMMED TO DO. If the program is wrong, the whole operation goes down the drain with it. Moreover he should also be flexible and have a fast turn-around because a CNC machine is often used to machine a huge selection of different work-pieces.

The Technician

The third person that will need is the CNC technician. Although this may still be the programmer, it is more convenient to always have a technical expert on-call because in the long run, you may have more than one CNC machine and you may need to prioritize over the other in case both gets crippled at the same time. Just like the programmer, the technician should also be flexible and articulate. CNC offers a lot of complexity when it is running right, how much more if it is behaving badly?

So, if you are having job openings for positions that need to be handling a CNC machine, ask the applicants first to do a demo for you and make sure that during the demo, they know what they're doing. An exam may also do wonders too. If they have no experience with any kind of CNC machine, it is advisable that you encourage them to take short courses on CNC.

Eighty-hour courses are available online and hey, it is better than nothing. Experts even encourage employers to hire CNC machinists who have finished AND PASSED the National Occupational Competency Testing Institute (NOCTI) assessment just so they could be sure that their CNC machines will go to good hands. After all, a CNC machine is still an asset.

The Operator

The second person that you need is the CNC operator. He will simply recheck the programs loaded to the machine and push the right buttons to get the work done. However, thinking that a CNC operator can have little or NO SKILL AT ALL is wrong. A CNC machine operator must have at least basic machining skills and he should have undergone some form of training to run a CNC machine.

These machines can produce very intricate motions, making it possible to make shapes that cannot be created on conventional machine tools. So, the operator should foresee this complexity and know how to cruise with it. The skills that an operator must have though, are lesser compared to the operators of conventional machine tools.